Masale a ho roala a Tungsten Carbide bakeng sa Indasteri ea Oli le Khase

Tlhaloso e Khutšoanyane:

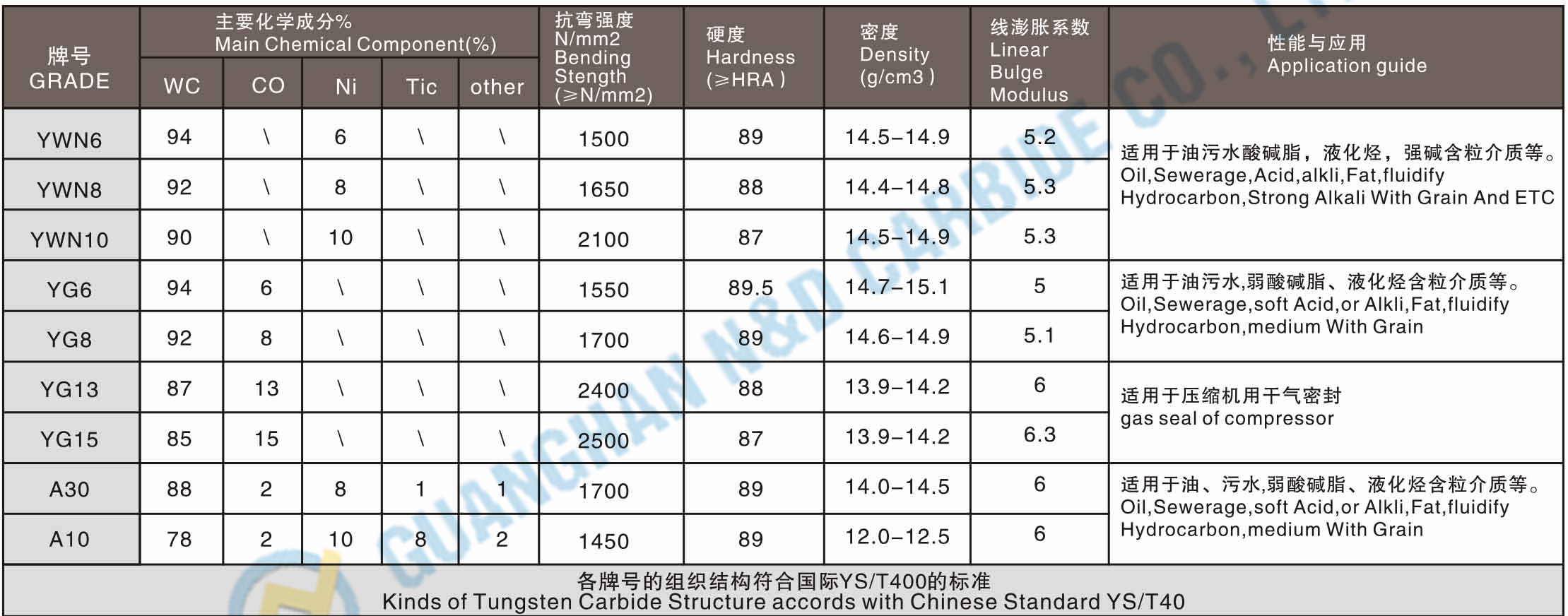

* Tungsten Carbide, Nikele/Cobalt Binder

* Libeso tsa Sinter-Hip

* Mechini ea CNC

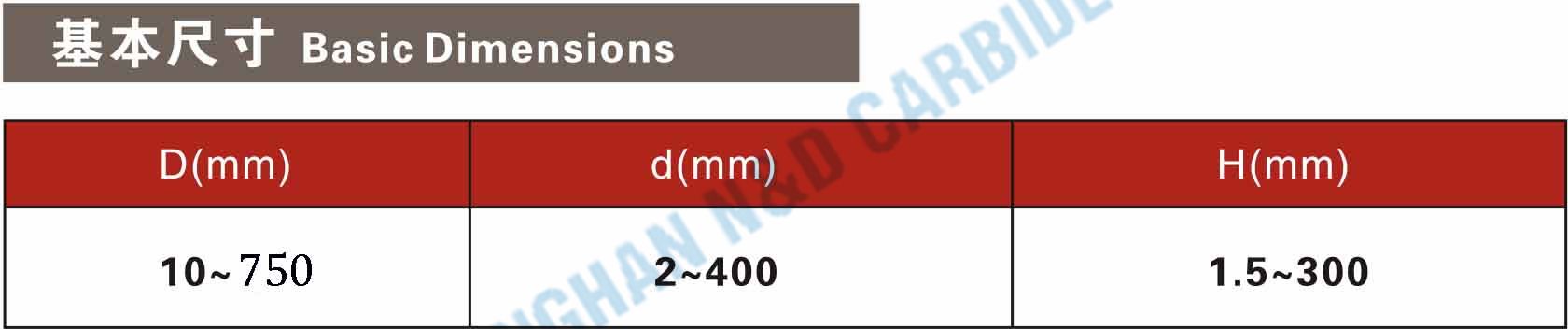

* Bophara ba Kantle: 10-750mm

* E sintered, e qetilwe e tloaelehileng, le ho lahlela seiponeng;

* Boholo bo eketsehileng, mamello, limaraka le bongata lia fumaneha ha ho kopuoa.

Lesale la ho roala la tungsten carbide le entsoe bakeng sa ho tšoarella ho sa bapisoeng le tikolohong e nang le khatello e phahameng, mocheso o phahameng le e senyang. Jwalo ka moetapele ditharollong tse tswetseng pele tsa thepa, re fana ka masale a tiiso a entsweng ka nepo a hlalosang tshebetso ditirisong tsa indasteri.

Masale a ho roala a Tungsten Carbide a sebelisoa haholo e le lifahleho tsa tiiso litiisong tsa mechini bakeng sa lipompo, li-compressor mixers le li-agitator tse fumanoang libakeng tsa ho hloekisa oli, lifemeng tsa petrochemical, lifemeng tsa manyolo, lifemeng tsa biri, merafong, lifemeng tsa pulp, le indastering ea meriana. Lesale la tiiso le tla kenngoa 'meleng oa pompo le axle e potolohang, 'me le etse tiiso ea metsi kapa ea khase ka lehlakoreng la pheletso la selikalikoe se potolohang le se sa sisinyeheng.

Maemo a Kopo

- Oli le Khase: Lisebelisoa tsa ho phunya kutu, lisebelisoa tsa ho phunya le litiiso tsa liphaephe.

- Ts'ebetso ea Lik'hemik'hale: Lipompo, li-reactor le li-valve tse sebetsanang le maro a matla.

- Mechine ea indasteri: Li-compressor, li-turbine le litsamaiso tsa hydraulic.

- Marine: Lisebelisoa tsa metsing a ka tlas'a lefatše le likarolo tse hanelang metsi a letsoai.

Ho na le khetho e kholo ea boholo le mefuta ea lesale la tungsten carbide, re ka boela ra khothaletsa, moralo,ntshetsa pele, hlahisa dihlahiswa ho ya ka ditshwantsho le ditlhoko tsa bareki.

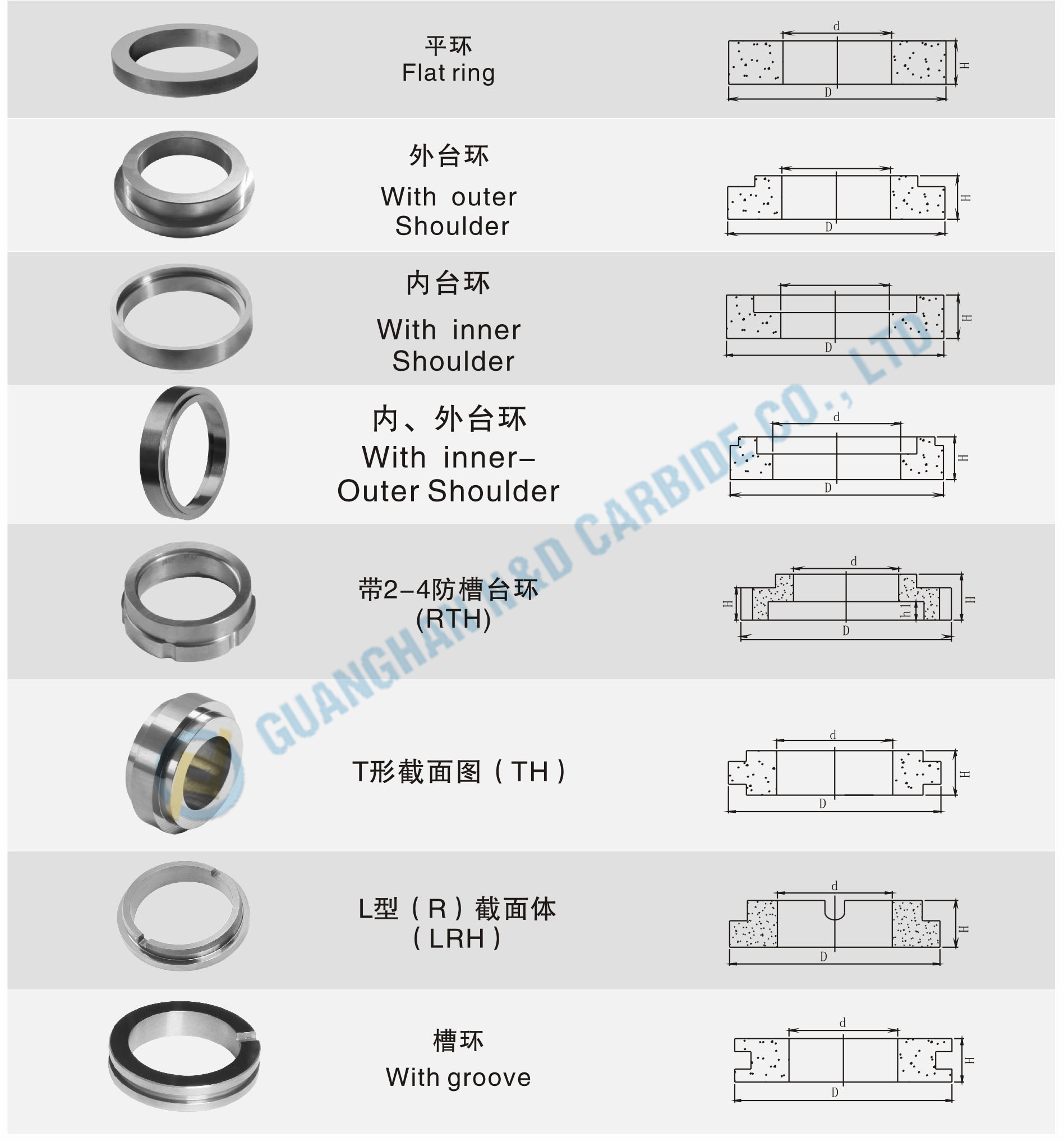

Masale a ho roala carbide ea tungsten a entsoe ka libopeho tse fapaneng ho ikamahanya le lisebelisoa tse fapaneng tsa ts'ebeliso.

Bakeng sa boiketlo ba hau, mefuta e meng e tloaelehileng ea lesale la TC ke ena:

Khanyetso e sa Bapisoeng ea ho Aparela

Lesale la ho apara la tungsten carbide le feta tšepe le letsopa libakeng tse khorofo, le netefatsa tahlehelo e fokolang ea thepa le bophelo bo bolelele ba ts'ebeletso. Ho thatafala ha eona ho feteletseng (Mohs 9-9.5) ho e etsa hore e be ntle bakeng sa maemo a khohlano e phahameng.

Tšireletso ea ts'enyeho

E etselitsoe ts'ebetso ea lik'hemik'hale le ts'ebeliso ea metsing, lesale la ho roala la tungsten carbide le hanela maro a mabifi le metsi a letsoai, le thibela ho senyeha le likotsi tsa ho lutla.

Boiketlo ba Thermal

E boloka botsitso ba sebopeho ho fihlela ho 500°C, e boloka lesale la ho roala la carbide ea tungsten le tiile ebile le se na phetoho tlas'a ts'ebetso ea mocheso o phahameng.

Nako e Atolositsoeng ea Bophelo

E fokotsa nako ea ho se sebetse ha tlhokomelo ka 50%+ ha e bapisoa le litiiso tse tloaelehileng, e fokotsa litšenyehelo tsa ts'ebetso le ho eketsa bokhoni liindastering tse kang oli le khase le merafo.

Ho iketsetsa

Li-geometri tse etselitsoeng motho ka mong le lipheletso tsa bokaholimo li ntlafatsa lesale la ho roala la carbide ea tungsten bakeng sa litlhoko tse itseng, ho tloha ho sebetsa ka nepo ho isa ho tsamaisong ea mokelikeli o nang le khatello e phahameng.

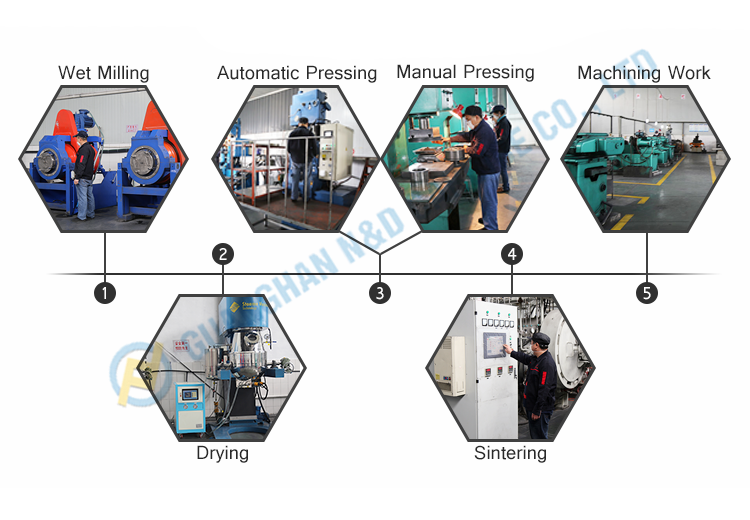

- Tokisetso ea Thepa: Phofo ea tungsten carbide e hloekileng haholo e kopantsoe le cobalt binder bakeng sa ho thatafala le ho tiea ka ho fetisisa.

- Ho hatella le ho Sintering: Ho hatelloa ha khatello e phahameng ho lateloa ke ho sintering ho laoloang ho netefatsa hore ho na le masoba a fokolang le ho ba le letsoalo le phahameng.

- Ho Sila ka ho Nepahala: Ho sila ho laoloang ke khomphutha ho fihlella ho nepahala ha boemo ba micron bakeng sa libaka tse phethahetseng tsa ho koala.

- Kalafo ea Bokaholimo: Liaparo tse sa hlokeheng li ntlafatsa ho hanyetsa mafome le ho fokotsa khohlano.

Guanghan ND Carbide e hlahisa mefuta e mengata ea tungsten carbide e sa tsofaleng le e sa senyeheng.

likarolo.

*Mehele ea tiiso ea mechini

*Lihlahla, Matsoho

*Linotlolo tsa Tungsten Carbide

*AP| Bolo le Setulo

*Sefate sa ho thiba, Setulo, Lihoko, Diski, Setha sa ho Phalla..

*Tungsten Carbide Burs/ Lithupa/Lipoleiti/Li-Strip

*Likarolo tse ling tsa tungsten carbide tse entsoeng ka mokhoa o ikhethileng

-- ...

Re fana ka mefuta e felletseng ea limaraka tsa carbide ho li-binder tsa cobalt le nickel.

Re sebetsana le lits'ebetso tsohle ka tlung ho latela litšoantšo tsa bareki ba rona le litlhaloso tsa thepa. Leha o sa bone

E thathamise mona, haeba o na le mehopolo eo re tla e hlahisa.

P: Na u khoebo ea k'hamphani kapa moetsi?

A: Re moetsi oa tungsten carbide ho tloha ka 2004. Re ka fana ka sehlahisoa sa tungsten carbide sa lithane tse 20 ka 'ngoe.khoeli. Re ka fana ka lihlahisoa tsa kharbide tse ikhethileng ho latela litlhoko tsa hau.

P: Nako ea hau ea ho tlisa thepa e nka nako e kae?

A: Ka kakaretso e tla nka matsatsi a 7 ho isa ho a 25 kamora hore odara e tiise. Nako e itseng ea ho fana e ipapisitse le sehlahisoa se itseng.le bongata boo u bo hlokang.

P: Na le fana ka disampole? Na ke mahala kapa ke tefiso?

K: E, re ka fana ka sampole mahala empa thepa e lefelloa ka litšenyehelo tsa bareki.

P. Na o leka thepa yohle ya hao pele o e tlisa?

K: E, re tla etsa teko le tlhahlobo ea 100% lihlahisoa tsa rona tsa carbide tse entsoeng ka samente pele li tlisoa.

1. THEKO EA FEKERE;

2. Tsepamisa maikutlo lihlahisoa tsa carbide ka lilemo tse 17 ;

3.lSO le AP| moetsi ea netefalitsoeng;

4. Tšebeletso e etselitsoeng motho ka mong;

5. Boleng bo botle le phano e potlakileng ;

6. Ho sila ha sebōpi sa HlP ;

7. CNC machining;

8. Mofani oa khamphani ea Fortune 500 ;