Tungsten Carbide Nozzles

Tlhaloso e Khutšoanyane:

* Tungsten Carbide, setlamo sa cobalt

* Lisebelisuoa tsa Sinter-HIP

* CNC Machining

* Ho roala ha metsi

* Tšebeletso e hlophisitsoeng

Li-nozzles tsa tungsten carbide li tla sebelisoa haholo-holo ho li-drill tsa PDC le li-cone roller bakeng sa ho phunya, ho pholisa le ho tlotsa malebela a ho cheka le ho hloekisa litsupa tsa majoe ka tlas'a seliba ka mokelikeli oa ho cheka maemong a ts'ebetso a khatello e phahameng, ho thothomela, lehlabathe le slurry. nakong ea ho batla oli le khase ea tlhaho.

Tungsten carbide sandblasting nozzles e entsoe ka ho tobetsa ho chesang ka mofuta o otlolohileng oa bore le mofuta oa venturi bore. Ka lebaka la ho thatafala ha eona, boima bo tlase le moaparo o motle haholo le ho thibela ho bola, nozzle ea Tungsten carbide sandblasting e 'nile ea sebelisoa haholo lisebelisoa tsa ho phunya lehlabathe le ho thunya, e fana ka bophelo bo bolelele ka moea o nepahetseng le tšebeliso e mpe.

Tungsten carbide spray nozzle ea tšimo ea oli e na le litlhaloso tse fapaneng, e sebetsoa le ho etsoa ka thepa e tala ea boleng bo holimo. E na le litšobotsi tsa ho hanyetsa mocheso o phahameng, ho hanyetsa kutu, ho hanyetsa abrasion, ho nepahala ho phahameng joalo-joalo.

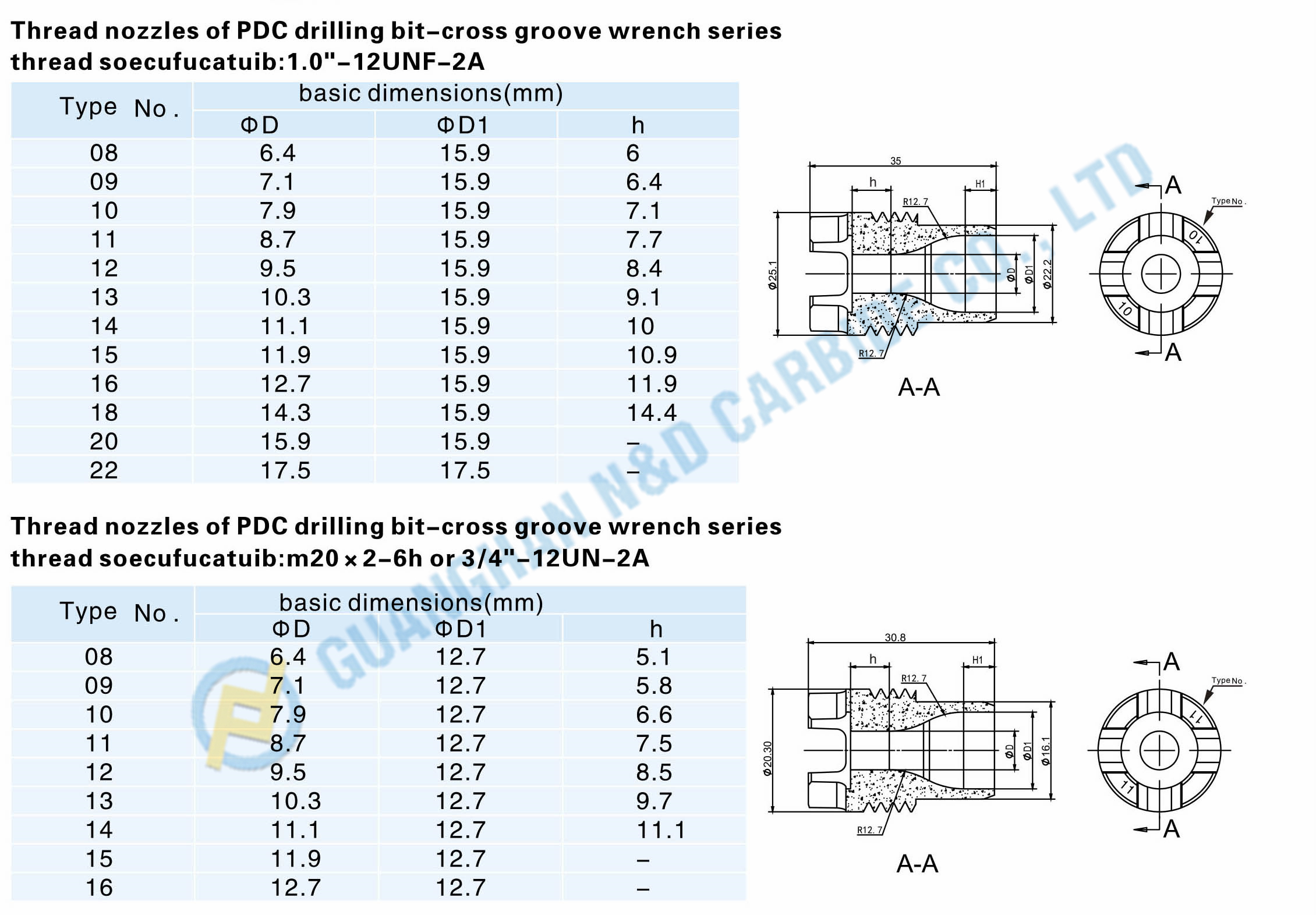

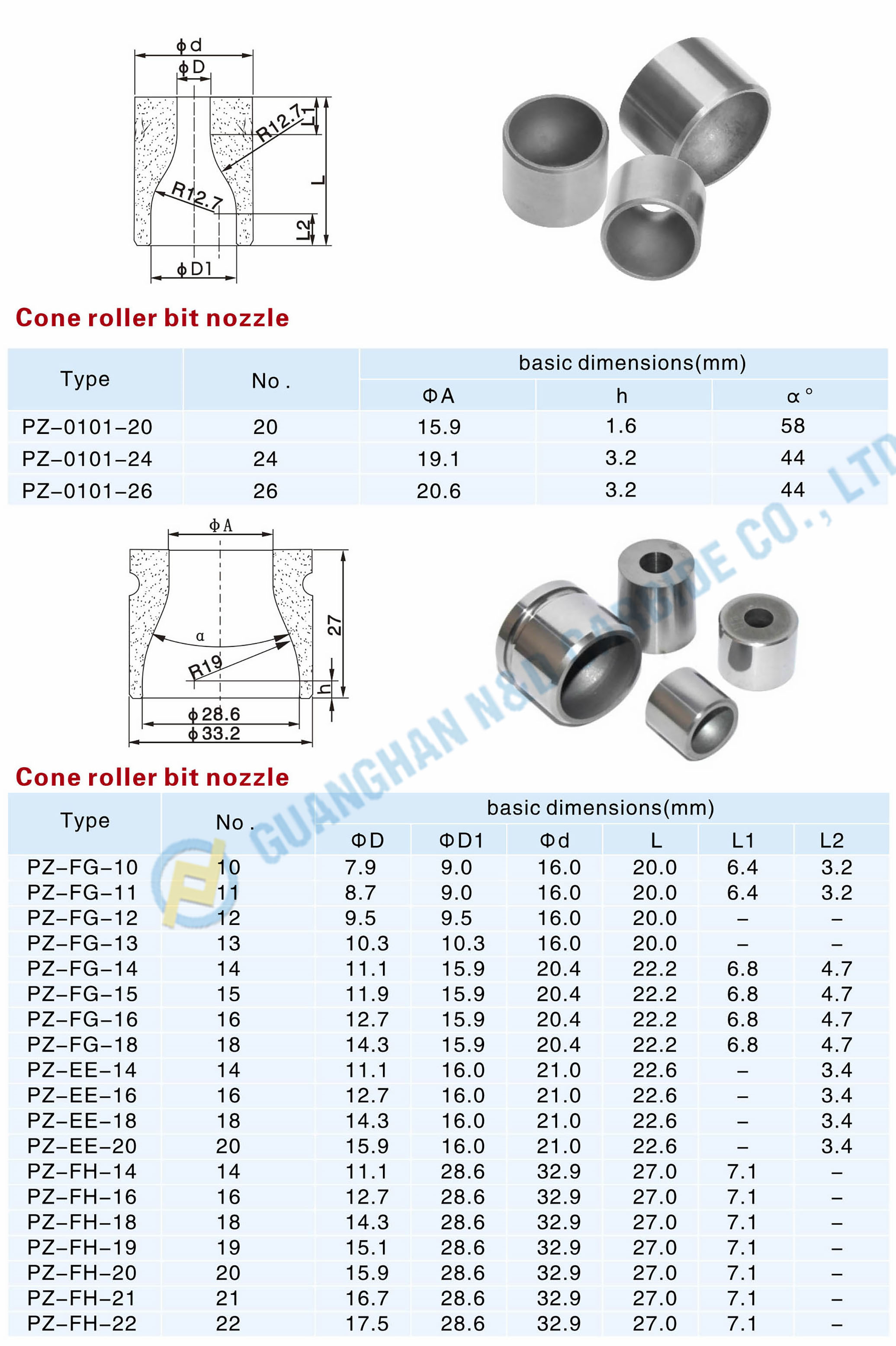

Tungsten carbide nozzle ea likarolo tsa ho cheka masimong a oli e fumaneha ka mefuta le boholo bo latelang:

li-nozzles tsa mofuta oa plum blossom

likhoele tse ka hare tse mahlakore a tšeletseng

likhoele tse ka ntle tse mahlakore a mararo

cross groove thread nozzles

Mofuta oa Y(li-grooves tse tharo) likhoele tsa likhoele

li-nozzles tse nyenyane tsa gear wheel drill ebe o tobetsa li-nozzles tse robehang.

Bakeng sa litlhoko tse fapaneng tsa bareki ba rona, re ikakhetse ka setotsoana ho hlahisa, ho fana, ho romela le ho rekisa mefuta e mengata ea Tungsten Carbide Nozzles. Lihlahisoa tsena li thata haholo 'me li netefatsa bophelo bo bolelele bo sebetsang. Lihlahisoa tsena kaofela li bonolo ho li kenya 'me li hloka tlhokomelo e tlaase. Lihlahisoa tsena li fumaneha ka boholo bo fapaneng le litlhaloso.

Lihlahisoa li na le ho apara hantle le ho hanyetsa tšusumetso. Khoele e ka etsoa ka carbide e tiileng kapa e sebelisitsoeng ho tiisa le ho beha theknoloji.