Li-nozzle tsa Tungsten Carbide

Tlhaloso e Khutšoanyane:

* Tungsten Carbide, sebindi sa cobalt

* Libeso tsa Sinter-Hip

* Mechini ea CNC

* Ho senyeha ha 'mele

* Tšebeletso e ikhethileng

Li-nozzle tsa carbide tsa tungsten li tla sebelisoa haholo-holo ho etsa li-drill bits tsa PDC le li-cone roller bits bakeng sa ho hlatsoa, ho pholisa le ho tlotsa lintlheng tsa drill bits le ho hloekisa li-chips tsa majoe ka tlase selibeng ka mokelikeli oa ho phunya maemong a ts'ebetso a khatello e phahameng, ho thothomela, lehlabathe le lerōle tse amang oli le khase ea tlhaho.

Linotlolo tsa ho qhaqha lehlabathe tsa Tungsten carbide li entsoe ka ho hatella ho chesang ka mofuta oa mokoti o otlolohileng le mokoti oa venturi. Ka lebaka la ho ba thata ha eona, ho ba le boima bo tlase le ho tsofala ho hoholo le ho thibela ho bola, mokoti oa ho qhaqha lehlabathe oa Tungsten carbide o 'nile oa sebelisoa haholo lisebelisoa tsa ho qhaqha lehlabathe le ho ntša metsi ka lithunya, o fanang ka bophelo bo bolelele ka tšebeliso e ntle ea moea le ho khohlela.

Notlolo ea spray ea tungsten carbide ea tšimo ea oli e na le litlhaloso tse fapaneng, e sebetsoang le ho etsoa ka thepa e tala ea boleng bo holimo. E na le litšobotsi tsa ho hanyetsa mocheso o phahameng, ho hanyetsa mafome, ho hanyetsa ho khoholeha, ho nepahala ho phahameng le tse ling.

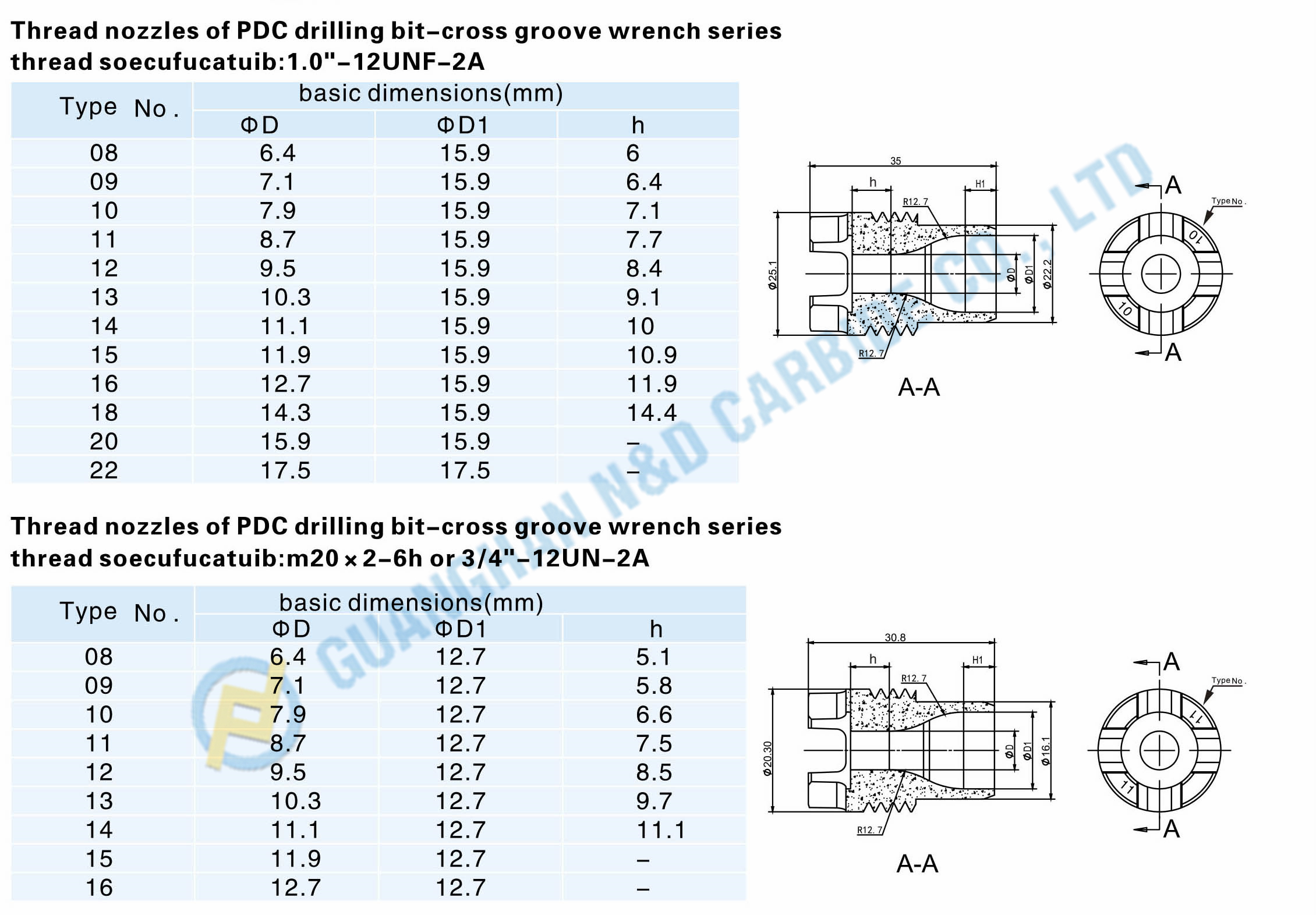

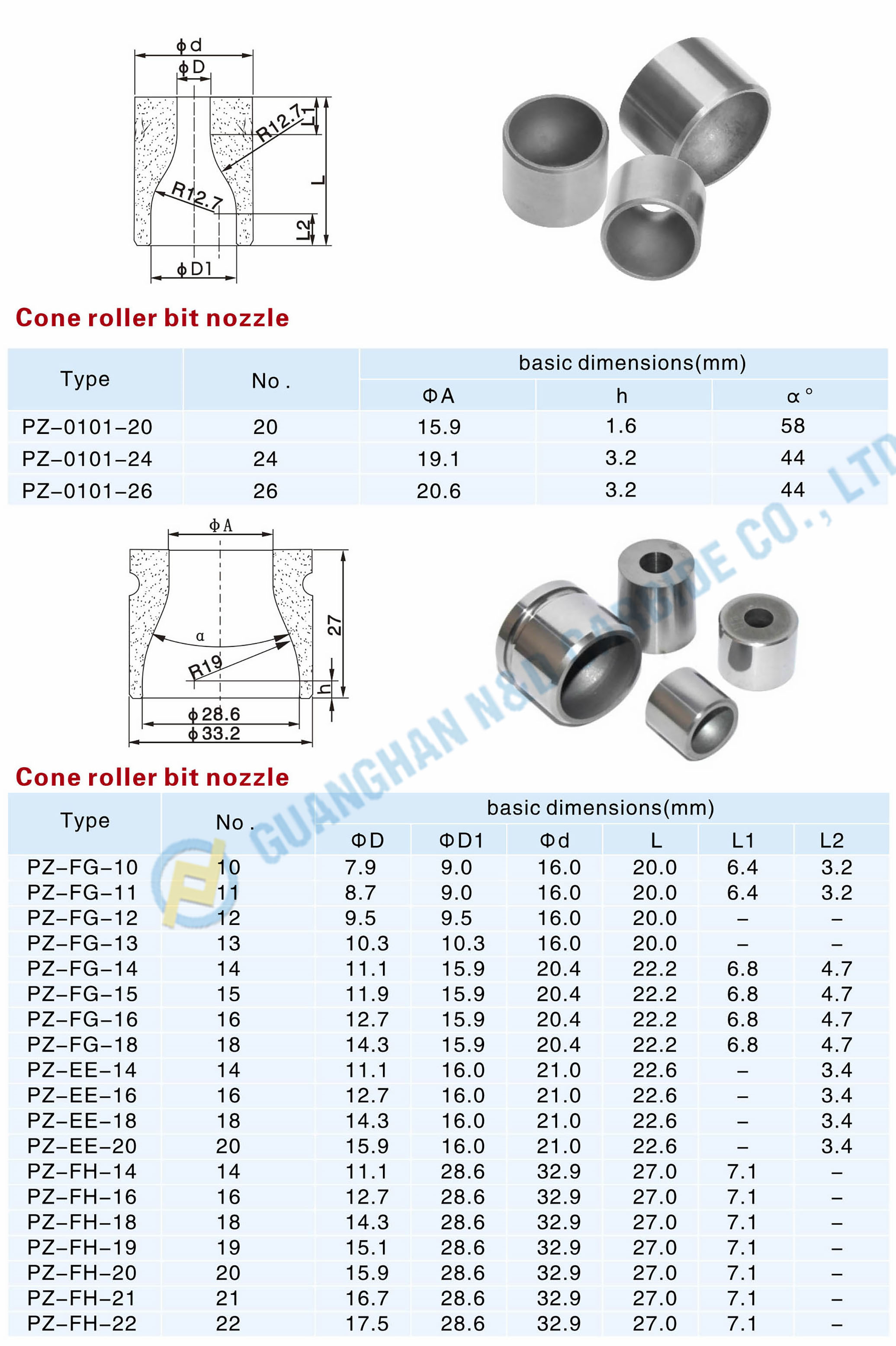

Nozzle ea tungsten carbide ea likarolo tsa ho phunya oli li fumaneha ka mekhoa le boholo bona:

li-nozzle tsa khoele tsa mofuta oa plum blossom

li-nozzle tsa khoele tse nang le mahlakore a tšeletseng ka hare

li-nozzle tsa khoele tse nang le mahlakore a tšeletseng a kantle

li-nozzle tsa khoele ea sefapano

Li-nozzle tsa khoele tsa mofuta oa Y (li-groove tse tharo)

li-nozzle tsa drill bit tsa lebili la gear le li-nozzle tsa press fracturing.

Bakeng sa litlhoko tse fapaneng tsa bareki ba rona, re phathahane ho hlahiseng, ho fepela, ho romela kantle le ho rekisa mefuta e mengata ea Linotlolo tsa Tungsten Carbide. Lihlahisoa tsena li tiile haholo 'me li netefatsa hore li sebetsa nako e telele. Lihlahisoa tsena kaofela li bonolo ho li kenya 'me li hloka tlhokomelo e tlase. Lihlahisoa tsena li fumaneha ka boholo le litlhaloso tse fapaneng.

Lihlahisoa li na le ho hanyetsa ho tsofala hantle le ho tetebela. Khoele e ka etsoa ka carbide e tiileng kapa theknoloji ea ho betla le ho seta e sebelisitsoeng.

Guanghan ND Carbide e hlahisa mefuta e mengata ea tungsten carbide e sa tsofaleng le e sa senyeheng.

likarolo.

*Mehele ea tiiso ea mechini

*Lihlahla, Matsoho

*Linotlolo tsa Tungsten Carbide

*Bolo le Setulo sa API

*Sefate sa ho thiba, Setulo, Lihoko, Diski, Setha sa ho Phalla..

*Tungsten Carbide Burs/ Lithupa/Lipoleiti/Li-Strip

*Likarolo tse ling tsa tungsten carbide tse entsoeng ka mokhoa o ikhethileng

-- ...

Re fana ka mefuta e felletseng ea limaraka tsa carbide ho li-binder tsa cobalt le nickel.

Re sebetsana le lits'ebetso tsohle ka tlung ho latela litšoantšo tsa bareki ba rona le litlhaloso tsa thepa. Leha o sa bone

E thathamise mona, haeba o na le mehopolo eo re tla e hlahisa.

P: Na u khoebo ea k'hamphani kapa moetsi?

A: Re moetsi oa tungsten carbide ho tloha ka 2004. Re ka fana ka sehlahisoa sa tungsten carbide sa lithane tse 20 ka 'ngoe.

khoeli. Re ka fana ka lihlahisoa tsa kharbide tse ikhethileng ho latela litlhoko tsa hau.

P: Nako ea hau ea ho tlisa thepa e nka nako e kae?

A: Ka kakaretso e tla nka matsatsi a 7 ho isa ho a 25 kamora hore odara e tiise. Nako e itseng ea ho fana e ipapisitse le sehlahisoa se itseng.

le bongata boo u bo hlokang.

P: Na le fana ka disampole? Na ke mahala kapa ke tefiso?

K: E, re ka fana ka sampole mahala empa thepa e lefelloa ka litšenyehelo tsa bareki.

P. Na o leka thepa yohle ya hao pele o e tlisa?

K: E, re tla etsa teko le tlhahlobo ea 100% lihlahisoa tsa rona tsa carbide tse entsoeng ka samente pele li tlisoa.

1. THEKO EA FEKERE;

2.Tlhahiso ea lihlahisoa tsa carbide tse tsepamisitsoeng ka lilemo tse 17;

3.lSO le moetsi ea netefalitsoeng oa AP|;

4. Tšebeletso e ikhethileng;

5. Boleng bo botle le phano e potlakileng;

6. Ho sila ha sebōpi sa HlP;

7. Mochini oa CNC;

8. Mofani oa k'hamphani ea Fortune 500.