Lesale la Tiiso la Tungsten Carbide le Ikhethileng bakeng sa Litiiso tsa Mechini

Tlhaloso e Khutšoanyane:

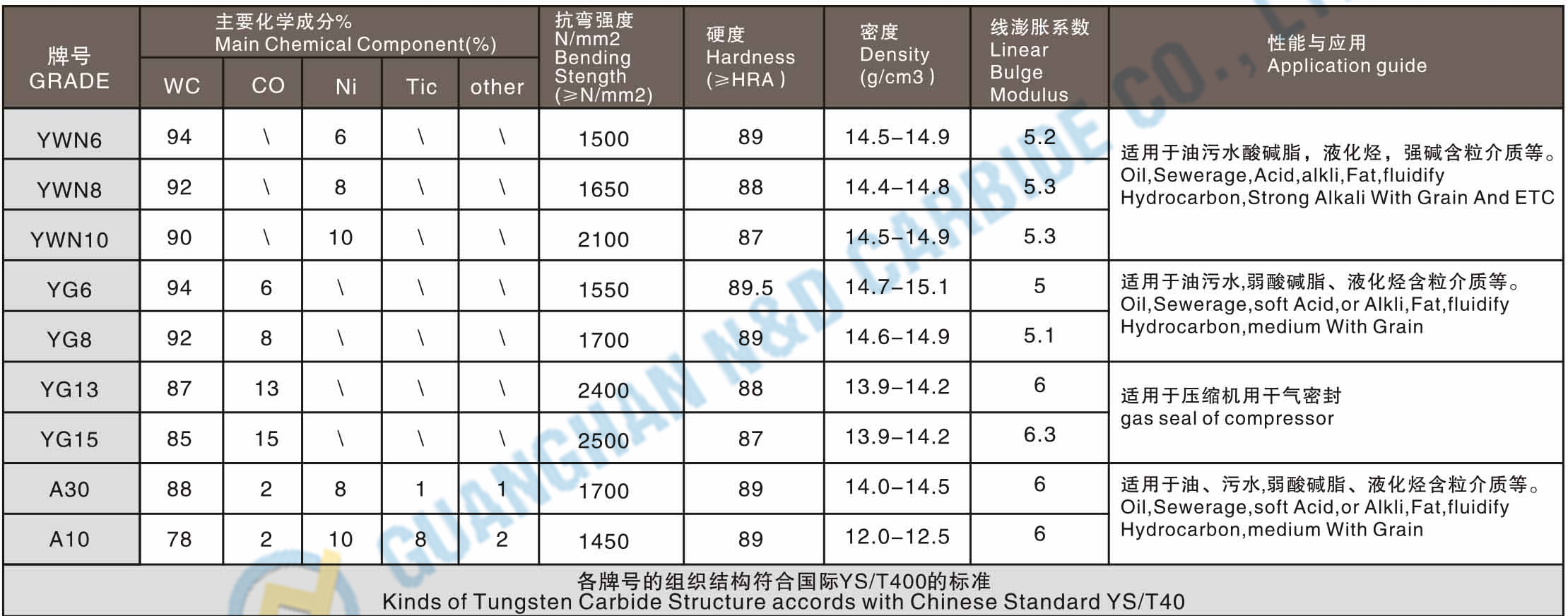

* Tungsten Carbide, Nikele/Cobalt Binder

* Libeso tsa Sinter-Hip

* Mechini ea CNC

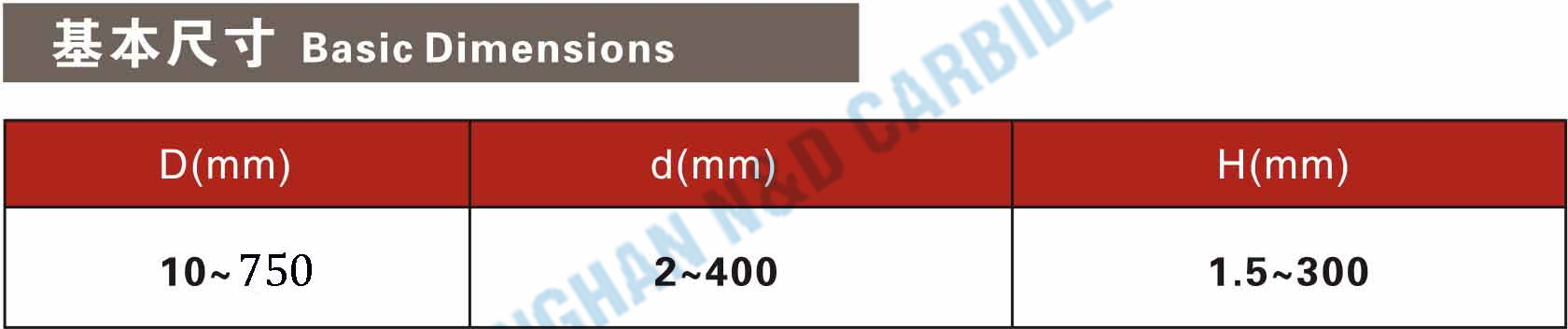

* Bophara ba Kantle: 10-800mm

* E sintered, e qetilwe e tloaelehileng, le ho lahlela seiponeng;

* Boholo bo eketsehileng, mamello, limaraka le bongata lia fumaneha ha ho kopuoa.

Re hlahisa lesale la rona la tiiso la Tungsten Carbide le ikhethileng bakeng sa litiiso tsa mechini, tharollo ea ho qetela ea ho netefatsa ts'ebetso e ntle le nako e telele lits'ebetsong tsa tiiso ea mechini. E entsoe ka ho nepahala le boiphihlelo, masale a rona a tiiso a etselitsoe ho mamella tikoloho ea indasteri e hlokang tlhokomelo e kholo, a fana ka khanyetso e ikhethang ea ho robeha le ts'epo.

Masale a rona a Tiiso a Tungsten Carbide a entsoe ka mokhoa o ikhethileng ho fihlela litlhoko tse ikhethileng tsa litiiso tsa mechini, ho netefatsa hore lia lekana hantle ebile li kopanngoa hantle. Ho thatafala le ho tiea ha tungsten carbide ho etsa hore e be thepa e loketseng bakeng sa masale a tiiso, ho fana ka khanyetso e ntle khahlanong le ho khoptjoa, mafome le mocheso o phahameng. Sena se bolela hore masale a rona a tiiso a ka thibela ho lutla le ho boloka tiiso e tiileng esita le maemong a thata ka ho fetisisa, qetellong a fokotsa litšenyehelo tsa tlhokomelo le nako ea ho se sebetse.

Ka boitlamo ba rona ba boleng le boqapi, re sebelisa mekhoa e tsoetseng pele ea tlhahiso ho hlahisa masale a tiiso a fetang maemo a indasteri. Lesale le leng le le leng le hlahlojoa ka hloko ho netefatsa ho nepahala le botsitso, ho netefatsa hore bareki ba rona ba fumana sehlahisoa sa boleng bo holimo.

Ntle le ts'ebetso ea tsona e ikhethang, masale a rona a tiiso a Tungsten Carbide a ikhethileng le 'ona a ka fetoloa haholo, a lumella litharollo tse etselitsoeng uena ho fihlela litlhoko tse ikhethileng tsa ts'ebeliso. Ebang ke boholo bo ikhethang, sebopeho, kapa litlhoko tse khethehileng tsa ho roala, re na le bokhoni ba ho fana ka masale a tiiso a etselitsoeng uena a lumellanang hantle le litlhaloso tsa bareki ba rona.

Ho feta moo, boinehelo ba rona ba ho kgotsofatsa bareki bo feta ka nqane ho sehlahiswa ka bosona. Re fana ka tshehetso e felletseng le boiphihlelo ba botekgeniki ho thusa bareki ba rona ho kgetheng lesale la tiiso le loketseng ka ho fetisisa bakeng sa ditshebediso tsa bona, hammoho le ho fana ka tataiso mabapi le mekgwa e metle ya ho kenya le ho hlokomela.

Qetellong, masale a rona a tiiso a Tungsten Carbide bakeng sa Litiiso tsa Mechini a fana ka ho tšoarella ho sa bapisoeng, ho tšepahala le likhetho tsa ho iketsetsa lintho, e leng se etsang hore e be khetho e ntle bakeng sa liindasteri moo litharollo tse tšepahalang tsa ho tiisa li leng tsa bohlokoa ka ho fetisisa. Tšepa boiphihlelo ba rona le boiphihlelo ba rona ho fana ka masale a tiiso a fetang litebello ka linako tsohle le ho kenya letsoho ts'ebetsong e se nang mathata ea litsamaiso tsa mechini.

Tungsten carbide (TC) e sebelisoa haholo e le lifahleho tsa seal kapa masale a nang le ho apara ho sa haneleng, matla a phahameng a ho phatloha ha fracture, conductivity e phahameng ea mocheso, katoloso e nyane ea mocheso e sebetsang hantle. Lesale la seal la tungsten carbide le ka aroloa ka bobeli ka lesale la seal le potolohang le lesale la seal le sa sisinyeheng. Mefuta e 'meli e tloaelehileng haholo ea lifahleho/lesale la seal la tungsten carbide ke sebinder sa cobalt le sebinder sa nickel.

Litiiso tsa mechine tsa tungsten carbide li ntse li sebelisoa haholo pompong ea metsi ho nkela sebaka sa setiiso sa tšoelesa e pakiloeng le molomo. Setiiso sa mechine sa tungsten carbide Pompo e nang le setiiso sa mechini e sebetsa hantle haholo 'me ka kakaretso e sebetsa ka mokhoa o tšepahalang haholoanyane ka nako e telele.

Ho ea ka sebopeho, litiiso tseo li boetse li bitsoa mehele ea tiiso ea mechine ea tungsten carbide. Ka lebaka la bokhabane ba thepa ea tungsten carbide, mehele ea tiiso ea mechine ea tungsten carbide e bontša ho tiea ho hoholo, 'me sa bohlokoa ka ho fetisisa ke hore li hanela ho bola le ho khoptjoa hantle. Ka hona, mehele ea tiiso ea mechine ea tungsten carbide e sebelisoa haholo ho feta litiiso tsa thepa e 'ngoe.

Sekoahelo sa mechine sa tungsten carbide se fanoa ho thibela mokelikeli o pompeloang ho tsoa ka har'a shaft ea drive. Tsela e laoloang ea ho lutla e pakeng tsa libaka tse peli tse bataletseng tse amanang le shaft e potolohang le ntlo ka ho latellana. Lekhalo la tsela ea ho lutla lea fapana ha lifahleho li le tlas'a mojaro o fapaneng oa kantle o atisang ho tsamaisa lifahleho tse amanang.

Lihlahisoa li hloka tokisetso e fapaneng ea moralo oa ntlo ea shaft ha e bapisoa le ea mofuta o mong oa tiiso ea mechini hobane tiiso ea mechini ke tokisetso e rarahaneng haholoanyane 'me tiiso ea mechini ha e fane ka tšehetso efe kapa efe ho shaft.

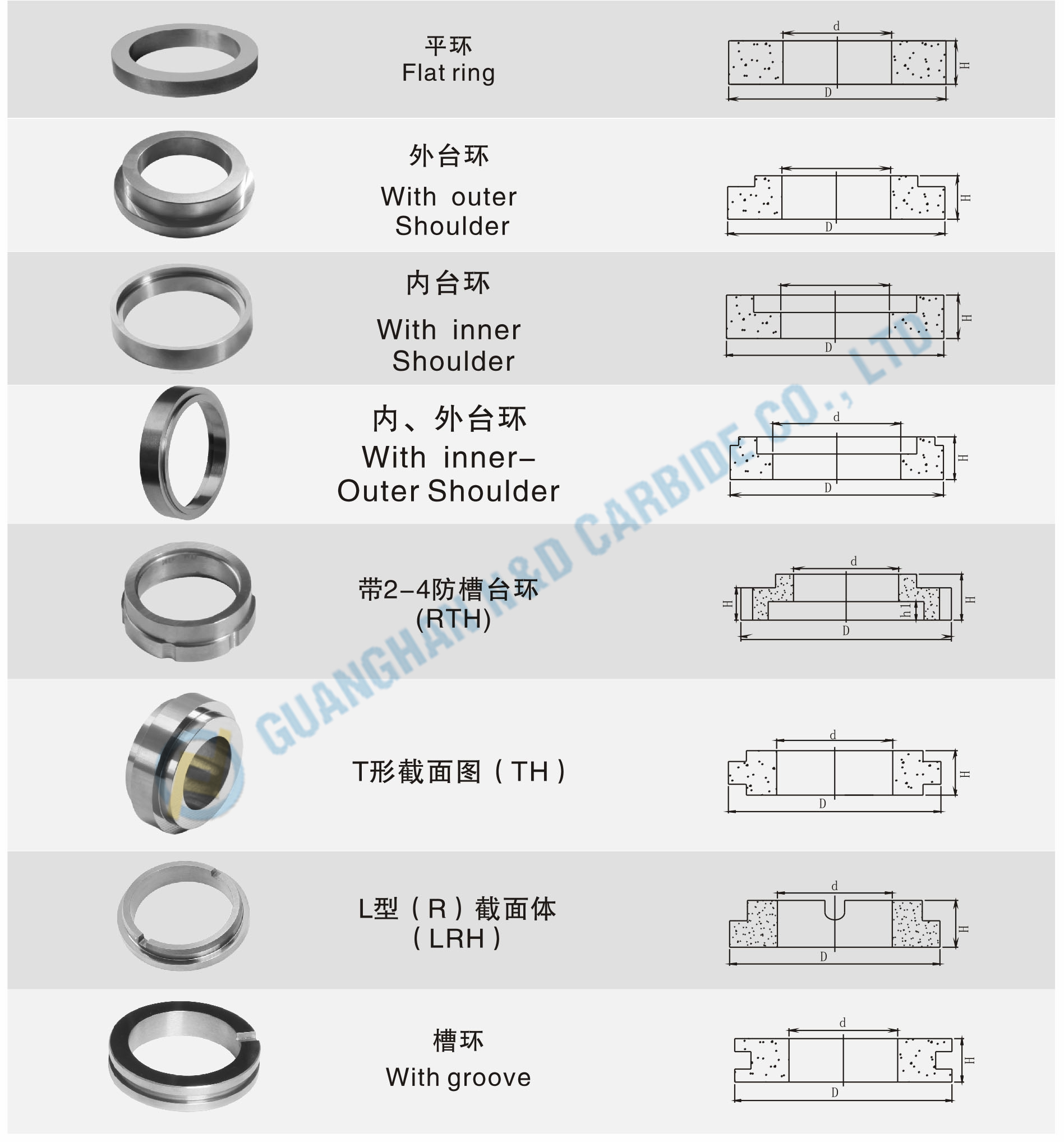

Mehele ea tiiso ea mechine ea Tungsten carbide e tla ka mefuta e 'meli ea mantlha:

Ho tlangwa ka cobalt (tshebediso ya ammonia e lokela ho qojwa)

Nickel e tlamiloeng (E ka sebelisoa ho Ammonia)

Hangata thepa ea ho kopanya ea 6% e sebelisoa masaleng a tiiso a mechini a tungsten carbide, leha ho le joalo mefuta e mengata e fumaneha. Masale a tiiso a mechini a tungsten carbide a kopantsoeng le nickel a atile haholo 'marakeng oa pompo ea metsi a litšila ka lebaka la khanyetso ea 'ona e ntlafetseng ea mafome ha e bapisoa le thepa e tlamiloeng ka cobalt.

Masale a tiiso a Tungsten Carbide a sebelisoa haholo e le lifahleho tsa tiiso litiisong tsa mechini bakeng sa lipompo, li-compressor mixers le li-agitator tse fumanoang libakeng tsa ho hloekisa oli, lifemeng tsa petrochemical, lifemeng tsa manyolo, lifemeng tsa biri, merafong, lifemeng tsa pulp, le indastering ea meriana. Lesale la tiiso le tla kenngoa 'meleng oa pompo le axle e potolohang, 'me le etse tiiso ea metsi kapa ea khase ka lehlakoreng la pheletso la lesale le potolohang le le sa sisinyeheng.

Masale a ho tiisa a tungsten carbide, e le sehlahisoa sa motsoako se entsoeng ka lits'ebetso tsa tšepe ea phofo, a na le mefuta e mengata le ea bohlokoa ea lits'ebetso. Ka tlase ke tlhaloso e qaqileng ea boholo ba ts'ebeliso ea ona:

Liindasteri tsa ho Ntša Oli le Lik'hemik'hale

Liindastering tsa ho ntša oli le lik'hemik'hale, mehele ea ho tiisa carbide e ratoa haholo ka lebaka la ho hanyetsa ha eona ho tsofala ho makatsang, ho hanyetsa mafome le ho hanyetsa tšusumetso. Litšobotsi tsena li li nolofalletsa ho sebetsa ka botsitso ka nako e telele libakeng tse thata tsa mosebetsi, ho thibela ho lutla ho mahareng ka katleho le ho netefatsa polokeho ea tlhahiso. Mehele ea ho tiisa carbide e sebelisoa hangata e le likarolo tsa bohlokoa tsa ho tiisa lipompong tse fapaneng, li-compressor, li-valve le lisebelisoa tse ling.

Lekala la Tlhahiso ea Mechini

Masale a ho tiisa khabide le ona a bapala karolo ea bohlokoa lefapheng la tlhahiso ea mechini. A sebelisoa haholo litataisong tsa lisilindara tsa oli, mechini e fapaneng ea tlhahiso, le lisebelisoa tsa mechini tse iketsang, joalo ka litiiso bakeng sa likarolo tsa telescopic, oscillating, sliding, kobeha le ho potoloha. Ho thatafala ho hoholo le ho hanyetsa ho tsofala ha masale a ho tiisa khabide ho eketsa bophelo ba lisebelisoa haholo, ho fokotsa makhetlo a tlhokomelo le a ho nkela sebaka, le ho fokotsa litšenyehelo tsa ts'ebetso bakeng sa likhoebo.

Indasteri ea Lipalangoang

Masale a ho tiisa khabide a na le boemo ba bohlokoa indastering ea lipalangoang. A teng likoloing, lithuthuthung, le mechining e fapaneng ea ho sebetsana le temo, moo likarolo tse ngata tse thellang le tse potolohang li hlokang litiiso tse tšepahalang. Ts'ebetso ea ho tiisa ea likarolo tsena e ama ka kotloloho polokeho le ts'epo ea likoloi. Masale a ho tiisa khabide, ka ts'ebetso ea ona e ikhethang ea ho tiisa le ho hanyetsa ho tsofala, a fana ka tšireletso e tšepahalang bakeng sa likarolo tsena.

Indasteri ea Lisebelisoa

Masale a ho tiisa khabide le ona a bapala karolo ea bohlokoa indastering ea lisebelisoa. Kaha hangata lisebelisoa li sebetsa libakeng tse nepahetseng le tse tsitsitseng, litlhoko tsa likarolo tsa ho tiisa li phahame haholo. Masale a ho tiisa khabide, ka ho nepahala ha 'ona ho phahameng, ho hanyetsa mafome, le ho hanyetsa ho tsofala, a phethahatsa litlhoko tse thata tsa lisebelisoa bakeng sa likarolo tsa ho tiisa.

Masimo a Mang

Ho feta moo, masale a ho tiisa a carbide a sebediswa haholo makaleng a fapaneng a kang motlakase, tshepe, le tshebetso ya dijo. Indastering ya motlakase, a sebediswa bakeng sa ho tiisa disebediswa tsa ho hlahisa motlakase; lefapheng la tshepe, a sebediswa bakeng sa ho tiisa tlasa maemo a mocheso o phahameng le kgatello e phahameng; mme tsamaisong ya dijo, ho hanyetsa mafome le thepa ya bohloeki di etsa hore e be dikarolo tsa bohlokwa mefuteng ya tlhahiso ya dijo.

Ka bokhutšoanyane, masale a ho tiisa carbide, ka ts'ebetso ea ona e phahameng le mefuta e mengata ea ts'ebeliso, a bapala karolo ea bohlokoa liindastering tsa sejoale-joale. Ha theknoloji e ntse e tsoela pele 'me lits'ebetso li ntse li atoloha, menyetla ea' maraka ea masale a ho tiisa carbide e tla ba e tšepisang le ho feta.

Ho na le khetho e kholo ea boholo le mefuta ea lesale la tiiso le bataletseng la tungsten carbide, re ka boela ra khothaletsa, ra rala, ra nts'etsapele, ra hlahisa lihlahisoa ho latela litšoantšo le litlhoko tsa bareki.

Guanghan ND Carbide e hlahisa mefuta e mengata ea tungsten carbide e sa tsofaleng le e sa senyeheng.

likarolo.

*Mehele ea tiiso ea mechini

*Lihlahla, Matsoho

*Linotlolo tsa Tungsten Carbide

*Bolo le Setulo sa API

*Sefate sa ho thiba, Setulo, Lihoko, Diski, Setha sa ho Phalla..

*Tungsten Carbide Burs/ Lithupa/Lipoleiti/Li-Strip

*Likarolo tse ling tsa tungsten carbide tse entsoeng ka mokhoa o ikhethileng

-- ...

Re fana ka mefuta e felletseng ea limaraka tsa carbide ho li-binder tsa cobalt le nickel.

Re sebetsana le lits'ebetso tsohle ka tlung ho latela litšoantšo tsa bareki ba rona le litlhaloso tsa thepa. Leha o sa bone

E thathamise mona, haeba o na le mehopolo eo re tla e hlahisa.

P: Na u khoebo ea k'hamphani kapa moetsi?

A: Re moetsi oa tungsten carbide ho tloha ka 2004. Re ka fana ka sehlahisoa sa tungsten carbide sa lithane tse 20 ka 'ngoe.

khoeli. Re ka fana ka lihlahisoa tsa kharbide tse ikhethileng ho latela litlhoko tsa hau.

P: Nako ea hau ea ho tlisa thepa e nka nako e kae?

A: Ka kakaretso e tla nka matsatsi a 7 ho isa ho a 25 kamora hore odara e tiise. Nako e itseng ea ho fana e ipapisitse le sehlahisoa se itseng.

le bongata boo u bo hlokang.

P: Na le fana ka disampole? Na ke mahala kapa ke tefiso?

K: E, re ka fana ka sampole mahala empa thepa e lefelloa ka litšenyehelo tsa bareki.

P. Na o leka thepa yohle ya hao pele o e tlisa?

K: E, re tla etsa teko le tlhahlobo ea 100% lihlahisoa tsa rona tsa carbide tse entsoeng ka samente pele li tlisoa.

1. THEKO EA FEKERE;

2. Tsepamisa maikutlo lihlahisoa tsa carbide ka lilemo tse 17 ;

3.lSO le AP| moetsi ea netefalitsoeng;

4. Tšebeletso e etselitsoeng motho ka mong;

5. Boleng bo botle le phano e potlakileng ;

6. Ho sila ha sebōpi sa HlP ;

7. CNC machining;

8. Mofani oa k'hamphani ea Fortune 500.