Sefate sa Choke le Setulo

Tlhaloso e Khutšoanyane:

* Tungsten Carbide + thepa ea SS

* Libeso tsa Sinter-Hip

* Mechini ea CNC

* Ho Wellisa Silevera

* Setulo le kutu tse phethiloeng

* Mokhoa o ikhethileng oa khokahano

Tungsten carbide ke motsoako oa lik'hemik'hale tse sa tloaelehang o nang le liathomo tse ngata tsa tungsten le carbon. Tungsten carbide, e tsejoang hape e le "carbide e samentetsoeng", "alloy e thata" kapa "tšepe e thata", ke mofuta oa thepa ea metallurgic e nang le phofo ea tungsten carbide (foromo ea lik'hemik'hale: WC) le binder e 'ngoe (cobalt, nickel, jj.).

E ka hatelloa le ho etsoa ka dibopeho tse ikgethileng, e ka silwa ka nepo, mme e ka kopanngwa ka kapa ya hokelwa ho ditshipi tse ding. Mefuta le dikereiti tse fapaneng tsa carbide di ka etswa jwalo ka ha ho hlokahala bakeng sa tshebediso e rerilweng, ho kenyeletswa indasteri ya dikhemikhale, oli le kgase le lewatle jwalo ka disebediswa tsa merafo le ho seha, hlobo le die, dikarolo tsa ho tsofala, jj.

Carbide ea Tungsten e sebelisoa haholo mechineng ea indasteri, lisebelisoa tse sa tsofaleng le tse thibelang ho bola. Carbide ea Tungsten ke thepa e ntle ka ho fetisisa ea ho hanela mocheso le ho robeha ha thepa eohle e thata.

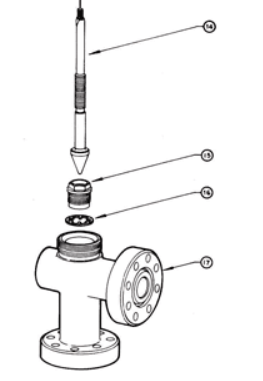

Valve ea choke ke sesebelisoa se sebelisetsoang ho laola phallo ea metsi a kang tlhahlobo ea seliba, lihlooho tsa liliba, ente ea molapo. Motsoako oa carbide o kentsoe ka nale ea kutu ea valve, setulo. Li-choke tse ntle li fana ka boemo bo tsitsitseng ba phallo ka khetho e kholo ea boholo le mefuta ea linaoa tse fumanehang. Li-choke tse fetoloang li fana ka sekhahla se feto-fetohang sa phallo empa li ka notleloa sebakeng haeba sekhahla se tsitsitseng sa phallo se hlokahala. Sekoti sa choke le setulo ke likarolo tsa bohlokoa bakeng sa li-valve tsa choke tse fetoloang lisebelisoa tsa hlooho ea liliba. Li kopantsoe ka lintlha tsa tungsten carbide le 'mele oa SS410/316. Ntlha ea carbide ea tungsten hammoho le kutu ea tšepe e sa hloekang e fana ka khanyetso e ntle ea ho roala maemong a ho hoholeha.

Sekotwana sa valve sa tungsten carbide choke le setulo tse ikgethileng ho latela ditshwantsho. Khamphani ya rona e na le mokgwa o ikgethang wa ho sebetsa ho hokela sekotwana le karolo e ka hare ho sona ho qoba bothata ba ho wa.

Guanghan ND Carbide e hlahisa mefuta e mengata ea tungsten carbide e sa tsofaleng le e sa senyeheng.

likarolo.

*Mehele ea tiiso ea mechini

*Lihlahla, Matsoho

*Linotlolo tsa Tungsten Carbide

*Bolo le Setulo sa API

*Sefate sa ho thiba, Setulo, Lihoko, Diski, Setha sa ho Phalla..

*Tungsten Carbide Burs/ Lithupa/Lipoleiti/Li-Strip

*Likarolo tse ling tsa tungsten carbide tse entsoeng ka mokhoa o ikhethileng

-- ...

Re fana ka mefuta e felletseng ea limaraka tsa carbide ho li-binder tsa cobalt le nickel.

Re sebetsana le lits'ebetso tsohle ka tlung ho latela litšoantšo tsa bareki ba rona le litlhaloso tsa thepa. Leha o sa bone

E thathamise mona, haeba o na le mehopolo eo re tla e hlahisa.

P: Na u khoebo ea k'hamphani kapa moetsi?

A: Re moetsi oa tungsten carbide ho tloha ka 2004. Re ka fana ka sehlahisoa sa tungsten carbide sa lithane tse 20 ka 'ngoe.

khoeli. Re ka fana ka lihlahisoa tsa kharbide tse ikhethileng ho latela litlhoko tsa hau.

P: Nako ea hau ea ho tlisa thepa e nka nako e kae?

A: Ka kakaretso e tla nka matsatsi a 7 ho isa ho a 25 kamora hore odara e tiise. Nako e itseng ea ho fana e ipapisitse le sehlahisoa se itseng.

le bongata boo u bo hlokang.

P: Na le fana ka disampole? Na ke mahala kapa ke tefiso?

K: E, re ka fana ka sampole mahala empa thepa e lefelloa ka litšenyehelo tsa bareki.

P: Na o leka thepa yohle ya hao pele o e tlisa?

K: E, re tla etsa teko le tlhahlobo ea 100% lihlahisoa tsa rona tsa carbide tse entsoeng ka samente pele li tlisoa.

1. THEKO EA FEKERE;

2. Tsepamisa maikutlo lihlahisoa tsa carbide ka lilemo tse 17 ;

3.lSO le AP| moetsi ea netefalitsoeng;

4. Tšebeletso e etselitsoeng motho ka mong;

5. Boleng bo botle le phano e potlakileng ;

6. Ho sila ha sebōpi sa HlP ;

7. CNC machining;

8. Mofani oa k'hamphani ea Fortune 500.